“Can you imagine how much fuel goes into radiator losses every day in America? A good spark-ignition engine is about 24 percent efficient ie., about 24 cents of your gasoline dollar ends up in power. (He uses rainwater in his testing.) Keeping the water from freezing will be another challenge.īut the inventor sees overriding benefits. Preliminary estimates suggest a Crower cycle engine will use roughly as many gallons of water as fuel.Īnd Crower feels the water should be distilled, to prevent deposits inside the system, so a supply infrastructure will have to be created. Offsetting that, of course, would be the need to carry large quantities of water, and water is heavier than gasoline or diesel oil. “In those big trucks, they look at payload as their bread and butter. “Especially an 18-wheeler, they’ve got that massive radiator that weighs 800, 1000 pounds.

SIX STROKE IC ENGINES FREE

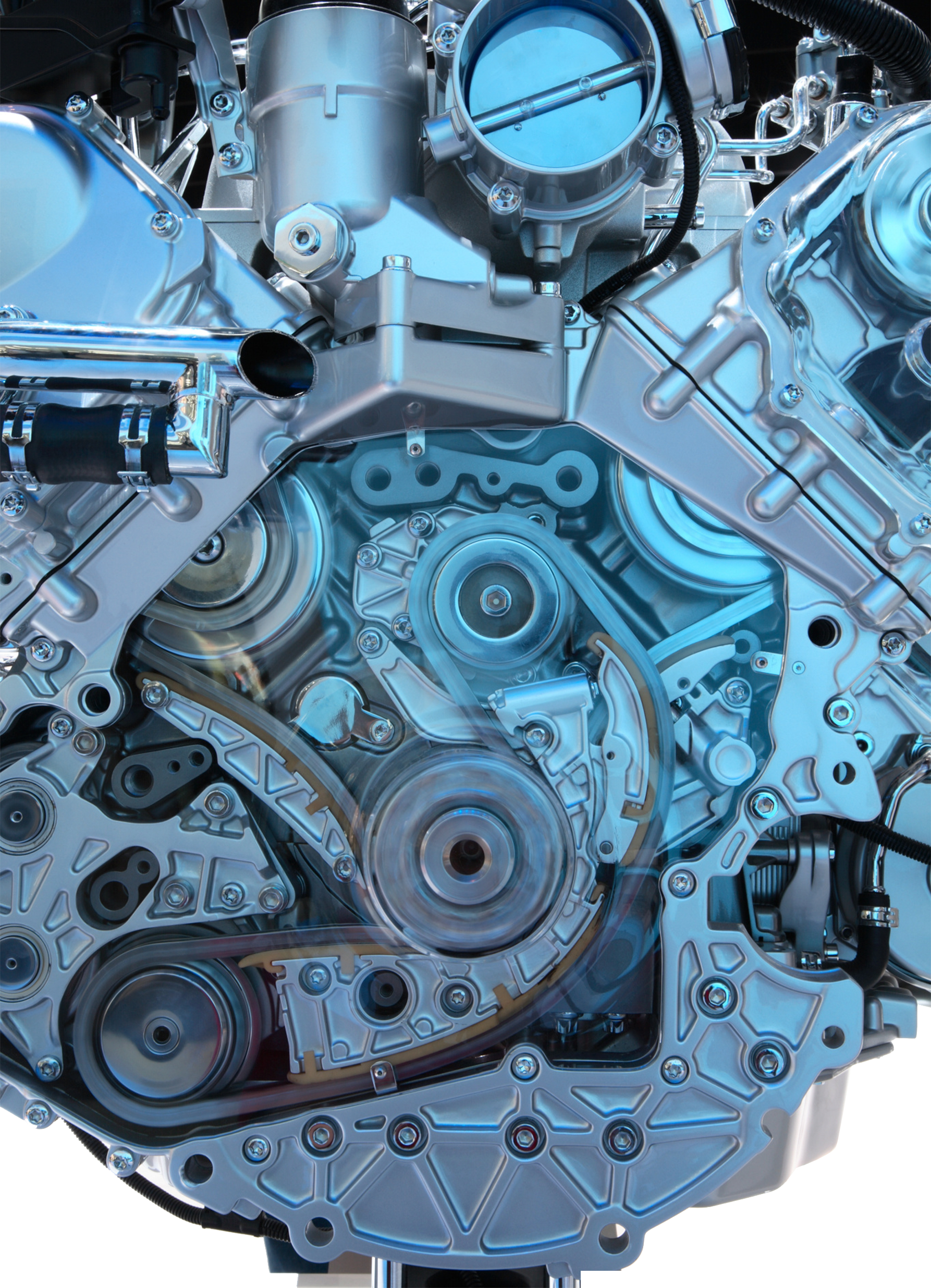

So far he has used only gasoline, but Bruce believes a diesel-fueled test engine he is now constructing-with a hand-made billet head incorporating the one-third-speed camshaft-will realize the true potential of his concept.Ĭrower invites us to imagine a car or truck (he speaks of a Bonneville streamliner, too) free of a radiator and its associated air ducting, fan, plumbing, coolant weight, etc. He has discarded the original cooling fan. It does retain fins because it came with them, but Crower indicates the engine would be more efficient if he took the trouble to grind them off. Indeed, the test unit has no external cooling system-no water jacket, no water pump, no radiator nothing. Any conventional engine running without a water jacket or fins, you couldn’t do that.”

It’s warm, yeah, but it’s not scorching hot. “It’ll run for an hour and you can literally put your hand on it.

The engine has yet to operate against a load on a dyno, but his testing to date encourages Crower to expect that once he gets hard numbers, the engine will show normal levels of power on substantially less fuel, and without overheating. Recently he’s been trying variations of the double-lobe exhaust cams to delay and even eliminate the opening of the exhaust valve after the first power stroke, to “recompress” the combustion gasses and thus increase the force of the steam-stroke. Over the following year Crower undertook a methodical development program, in particular trying out numerous variations in camshaft profiles and timing as he narrowed the operating parameters of his patented six-stroke cycle. The “snow” was flakes of white paint blasted from the ceiling by the powerful pulses of exhaust gas and steam emitted from the open exhaust stack, which pointed straight up. “And then this ‘snow’ started falling on me. “My first reaction was, ‘Gulp! It runs!’” the 75-year-old inventor remembers. He bolted that to a test frame, poured equal amounts of fuel and water into twin tanks, and pulled the starter-rope. Hurrying to his comprehensively-equipped home workshop in the rural hills outside San Diego, he began drawing and machining parts, and installing them in a highly modified, single-cylinder industrial powerplant, a 12-hp diesel he converted to use gasoline.

“One morning about 18 months ago I woke up, like from a dream, and I knew immediately that I had the answer.”

SIX STROKE IC ENGINES HOW TO

“I’ve been trying to think how to capture radiator losses for over 30 years,” explains the veteran camshaft grinder and race engine builder. Now he’s working on a cool one-one that harnesses normally-wasted heat energy by creating steam inside the combustion chamber, and using it to boost the engine’s power output and also to control its temperature. Bruce Crower has lived, breathed and built hot engines his whole life.

0 kommentar(er)

0 kommentar(er)